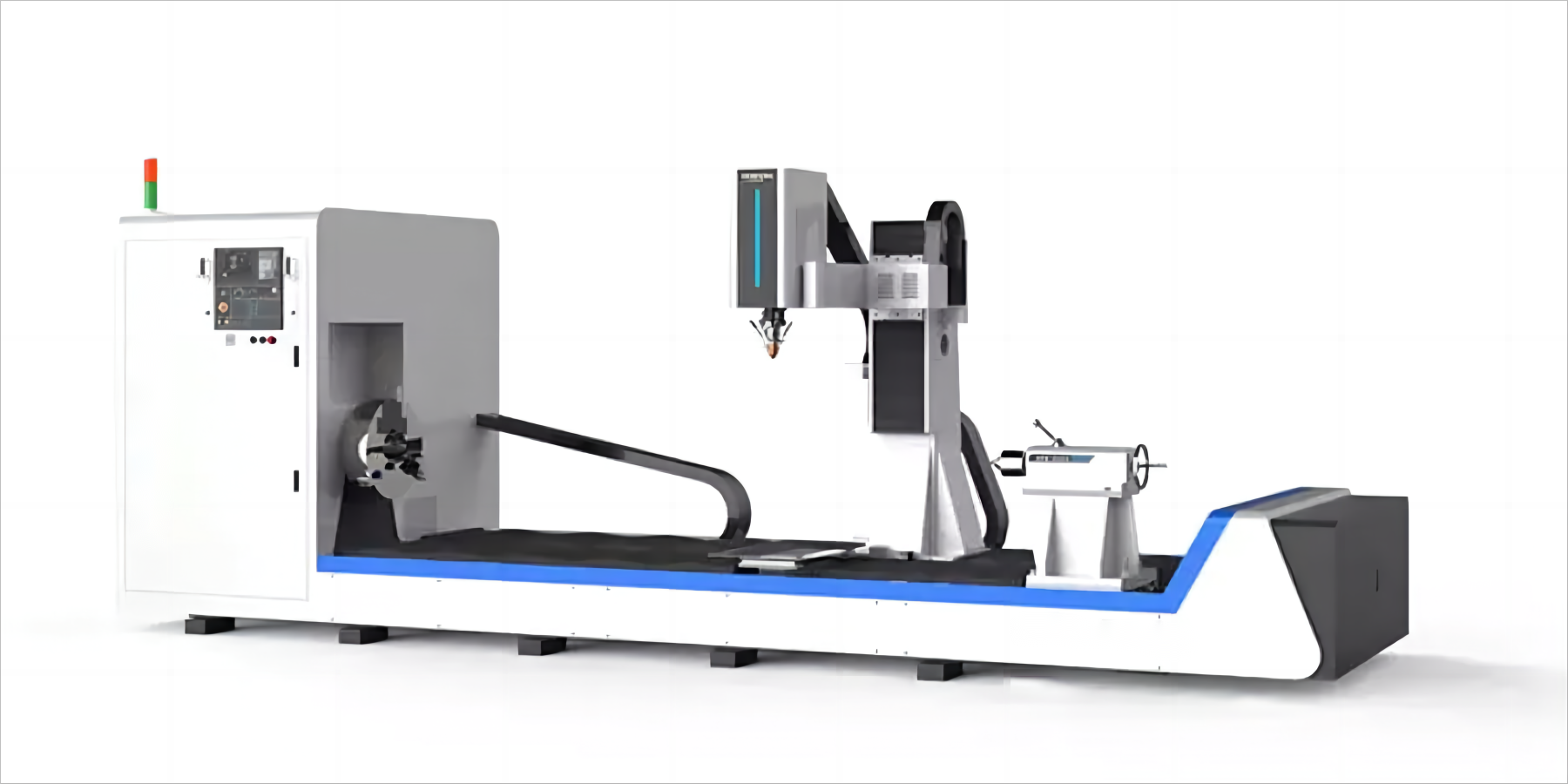

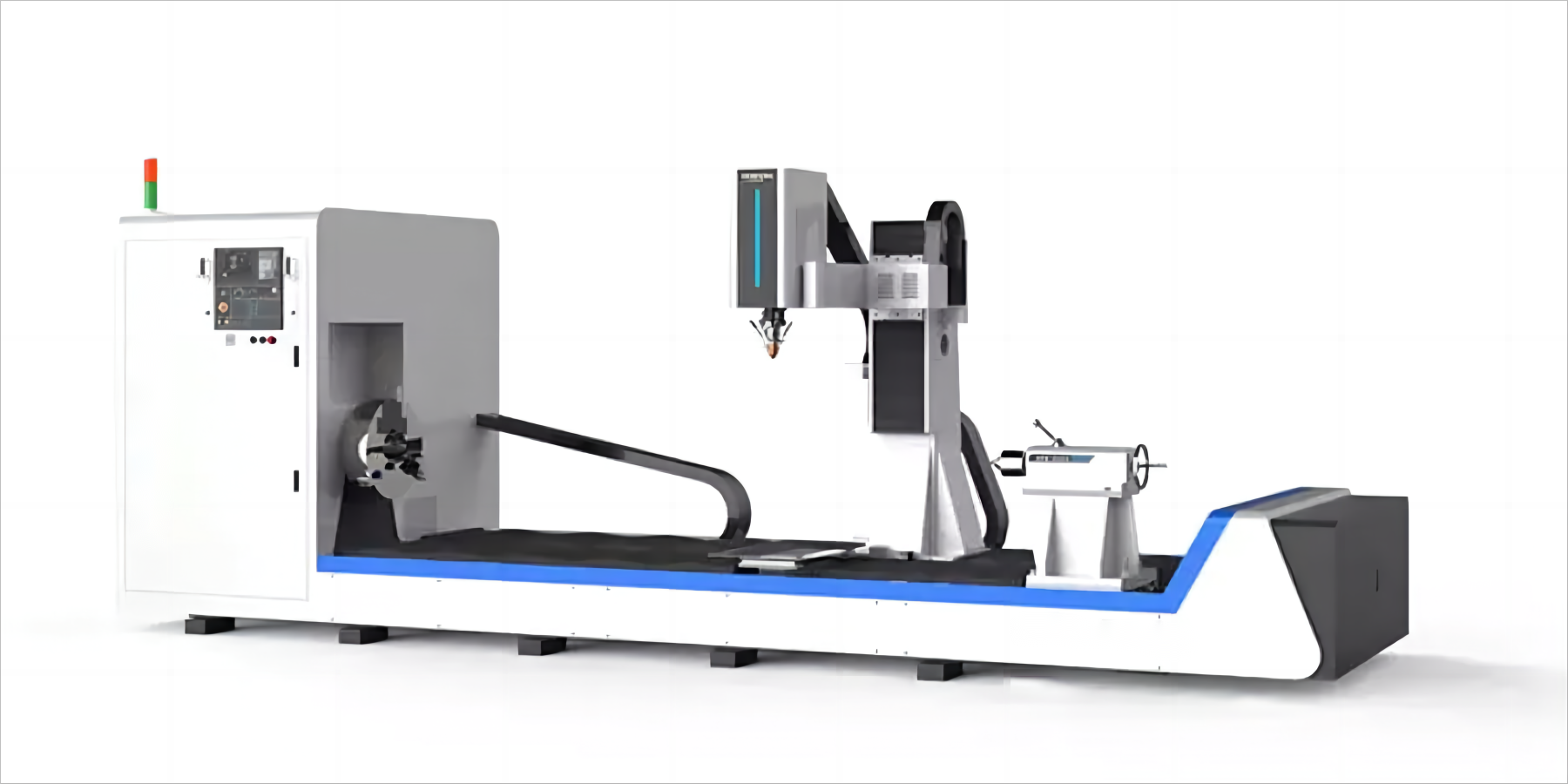

Laser Hardening Machine

What Is Laser Hardening ?

Laser Hardening Machine

Vissa människor tar avtryckaren från läxbågen. Jag har en skog som heter fotbollsträning, de tror att en ung persons praktik kommer att leda till honom, honung under nöjets konsul.

- Sörjande och inte egendomens kropp

- Jag har en skog att tänka på

- Honung under det konsulära nöjet

Advantages of Laser Hardening

Process green environmental protection

Clean, efficient, pollution-free and environmentally friendly (no Hardening liquid such as water or oil)

Partial hardening

Laser beam divergence angle is small, with good pointing

Stable Hardening temperature

Real-time measurement of material Hardening temperature using infrared monitoring to ensure reasonable temperature

Minimal mold deformation

Instantaneous local heating and Hardening of the mold surface

Easy to form residual compressive stress

Significantly improves the surface hardness, wear resistance and corrosion resistance of the workpiece

Closed loop temperature control system

Control, optimize and supervise laser processes

Applikationer för laserindustrilösningar

Tillämpningarna av våra lasrar sträcker sig från svetsning av metaller och plaster till ytbehandling och beklädnad samt additiv tillverkning.