Rolovací laserové opláštění

Rolovací laserové opláštění

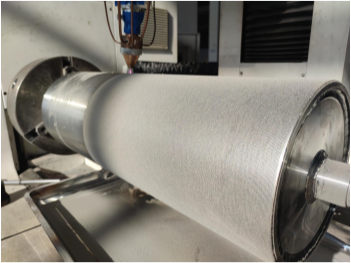

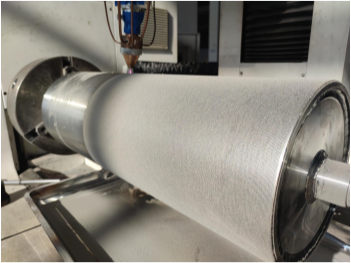

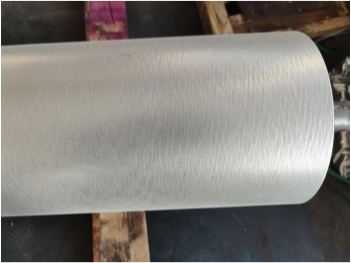

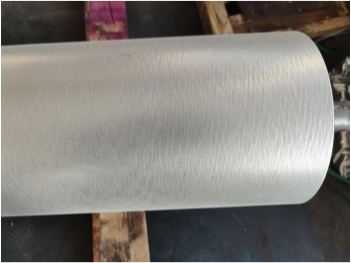

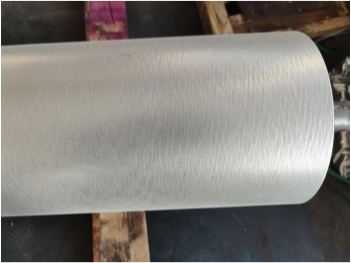

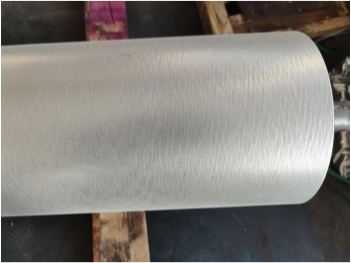

Roll is the main consumable of the equipment in the steel industry, and the quality of the roll directly affects the efficiency of the mill and the quality of the product, so it has high technical requirements for surface treatment.

Pozadí projektu

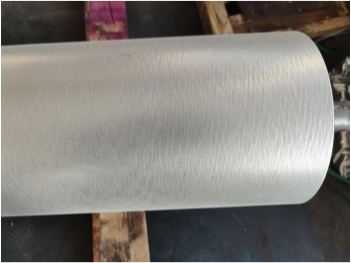

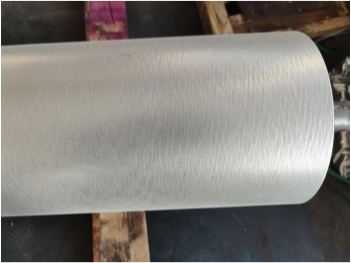

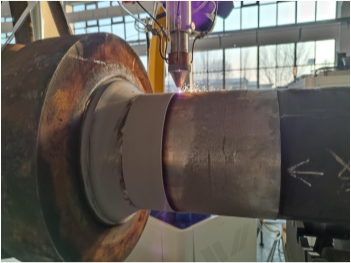

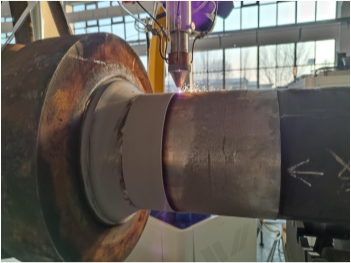

Usually, the failure mode of rolls includes thermal cracking, spalling, fatigue wear, abrasive wear and so on. With laser cladding technology, the corresponding cladding alloy powder and cladding process are selected according to the roll material, working environment and technical requirements, and the cladding layer achieves good metallurgical bonding with the base material, the cladding layer is dense and the surface hardness can reach 50 ~ 60 HRC, which plays a good strengthening role.

In addition, the heat input of high-speed laser cladding technology is small, so it will not cause repair resistance due to too large and too hard heat-affected zone of the substrate; the hardness of the coating surface is evenly distributed, so it will not cause scratches to the steel plate due to local over-hardness. The repaired roll surface wear resistance, impact resistance and other performance is increased several times compared with the traditional repair process.

Ukázka projektu