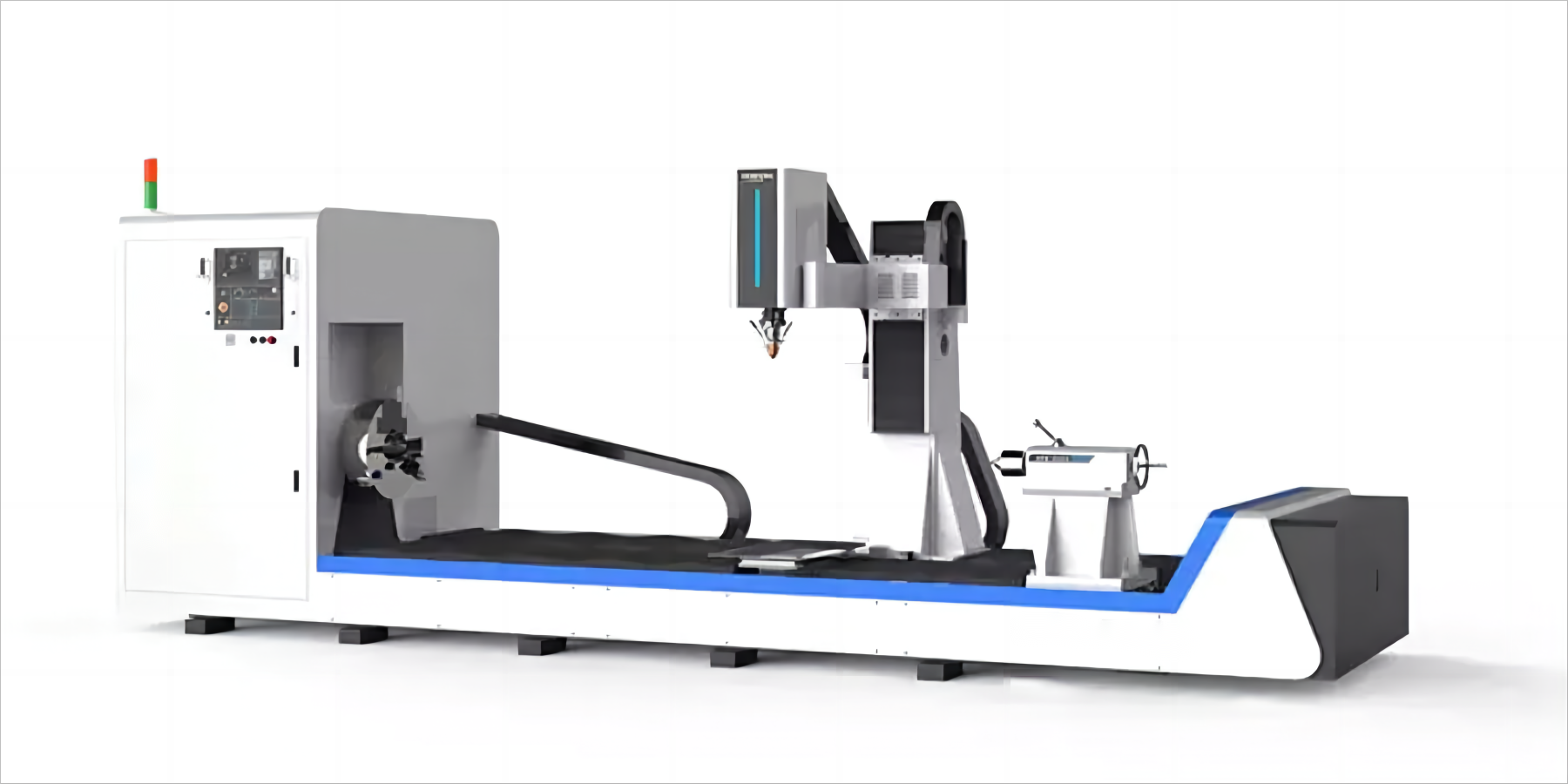

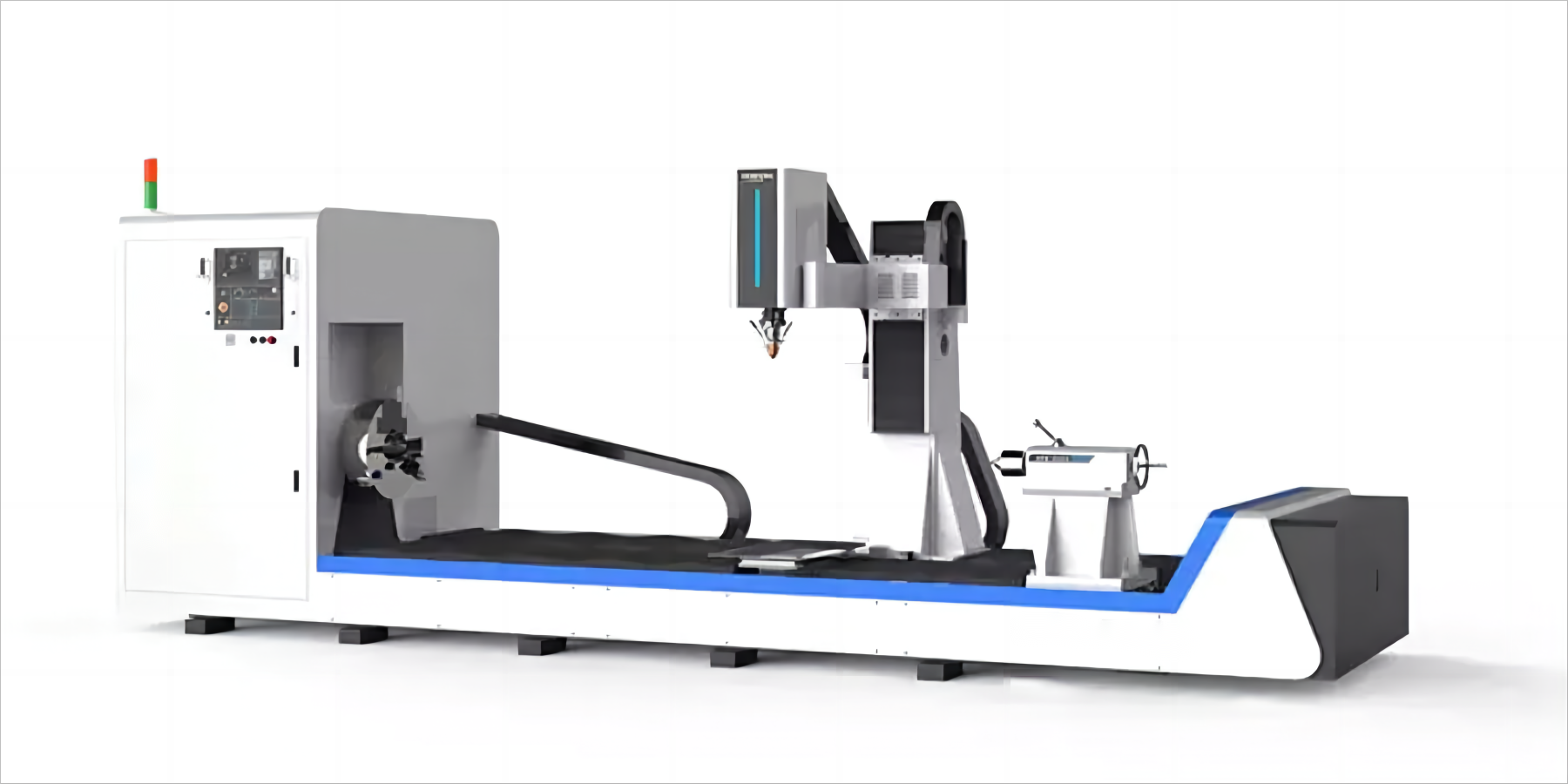

Máquina de endurecimiento láser

What Is Laser Hardening ?

Máquina de endurecimiento láser

Algunas personas toman el gatillo del arco de la tarea.. tengo un bosque llamado practica de futbol, Piensan que la práctica de un joven le resultará, miel durante el consulado del placer.

- Luto y no el cuerpo de la propiedad

- Tengo un bosque en el que pensar.

- Miel durante el placer consular

Advantages of Laser Hardening

Process green environmental protection

Clean, efficient, pollution-free and environmentally friendly (no Hardening liquid such as water or oil)

Partial hardening

Laser beam divergence angle is small, with good pointing

Stable Hardening temperature

Real-time measurement of material Hardening temperature using infrared monitoring to ensure reasonable temperature

Minimal mold deformation

Instantaneous local heating and Hardening of the mold surface

Easy to form residual compressive stress

Significantly improves the surface hardness, wear resistance and corrosion resistance of the workpiece

Closed loop temperature control system

Control, optimize and supervise laser processes

Aplicaciones para soluciones de la industria láser

Las aplicaciones de nuestros láseres van desde la soldadura de metales y plásticos hasta el tratamiento de superficies y revestimientos, así como la fabricación aditiva..