Reparação de disco foliar

Reparação de disco foliar

O disco de lâmina integral é um componente chave das peças do motor aeronáutico, a ponta da lâmina é facilmente desgastada durante o uso, e as extremidades da raiz da lâmina são propensas a falhas de rachaduras, levando à sucata. O uso da tecnologia de fabricação aditiva de reparo a laser pode ser alcançado em um curto período de tempo para obter a moldagem direta de todo o disco da folha, pode ser um ótimo programa para economizar custos e melhorar a eficiência da produção.

Histórico do projeto

The current manufacturing method of integral impeller uses forging, which has high forging cost and long cycle time, and the forged integral impeller will also have some metallurgical defects. The laser direct forming of aero-engine integral impeller can reduce the cost and speed up the cycle. The aero-engine integral impeller is prone to tip wear, cracking and other defects during use. In most cases, they are simply scrapped because they cannot be repaired. The cost of a direct replacement of an aero-engine impeller is very expensive, and the cost of a new product is generally not less than one million.

The whole leaf disc laser remanufacturing repair in foreign countries have successful cases, by foreign technical barriers, China in the whole blade of the laser remanufacturing technology has few successful applications. Portanto, the development of the overall leaf disc laser remanufacturing technology is an urgent technical problem to be solved.

Amostra de projeto

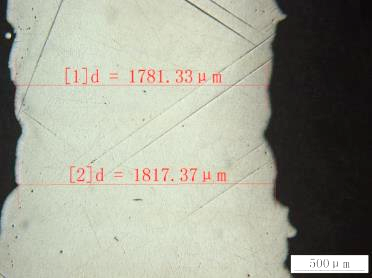

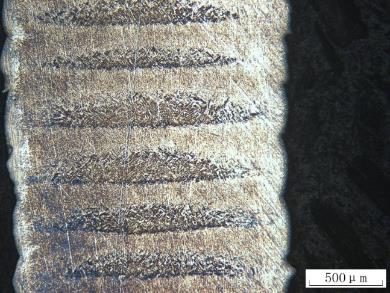

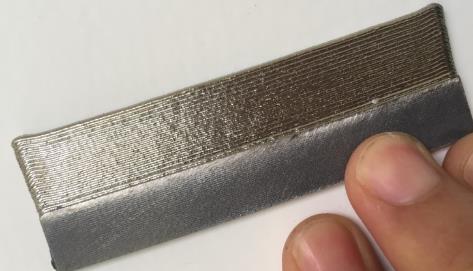

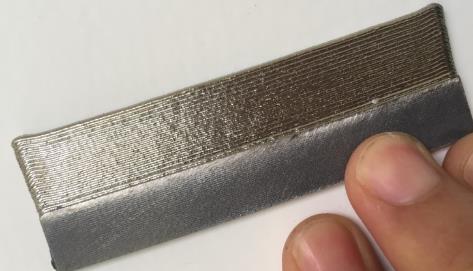

The overall leaf disc substrate material and laser cladding material are TC17, GH4169G. The laser cladding metallographic inspection meets the inspection requirements, with appropriate layer thickness, good side molding, no metallurgical defects, and uniform organization.

TC17 transverse cladding sample

Longitudinal cladding specimen

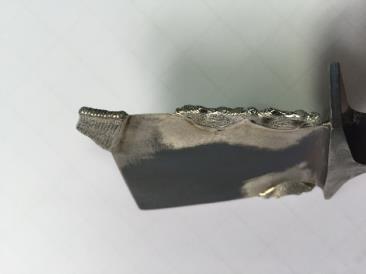

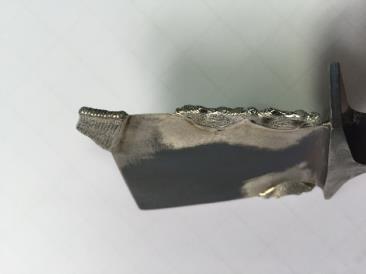

After the mechanical performance samples pass the test, the unit cladding and sample cladding repair are carried out. Man-made defects and repair defects by laser melting grid. In order to ensure the repair after cladding, a certain thickness needs to be guaranteed, and the scanning path needs to be designed according to the shape of the blade.

Through the cladding test of the single element, a viabilidade do revestimento, a estabilidade do processo, o efeito de revestimento da lâmina de elemento único, incluindo deformação, e a presença ou ausência de defeitos foram confirmadas, e a tolerância de usinagem e a deformação foram confirmadas através do reparo após o revestimento e assim por diante.

Single element notch cladding effect

Depois do revestimento, não há defeito na inspeção, e o resultado final atende ao padrão de aceitação do projeto.

TC17 sample blade cladding test

>>The overall blisk laser additive manufacturing repair project completed the following technical content, and all passed the assessment test

- 1、Research on laser cladding performance.

- 2、Conduct basic process development.

- 3、Design and development of tooling and equipment applicable to laser additive manufacturing of integral leaf discs

- 4、Research and development of additive manufacturing equipment and repair process technology applicable to the overall leaf disc.

- 5、Conduct repair test of unit part sample

- 6、To carry out repair test of the whole leaf disc.

- 7、Conduct mechanical property test, unit part and overall part repair test.