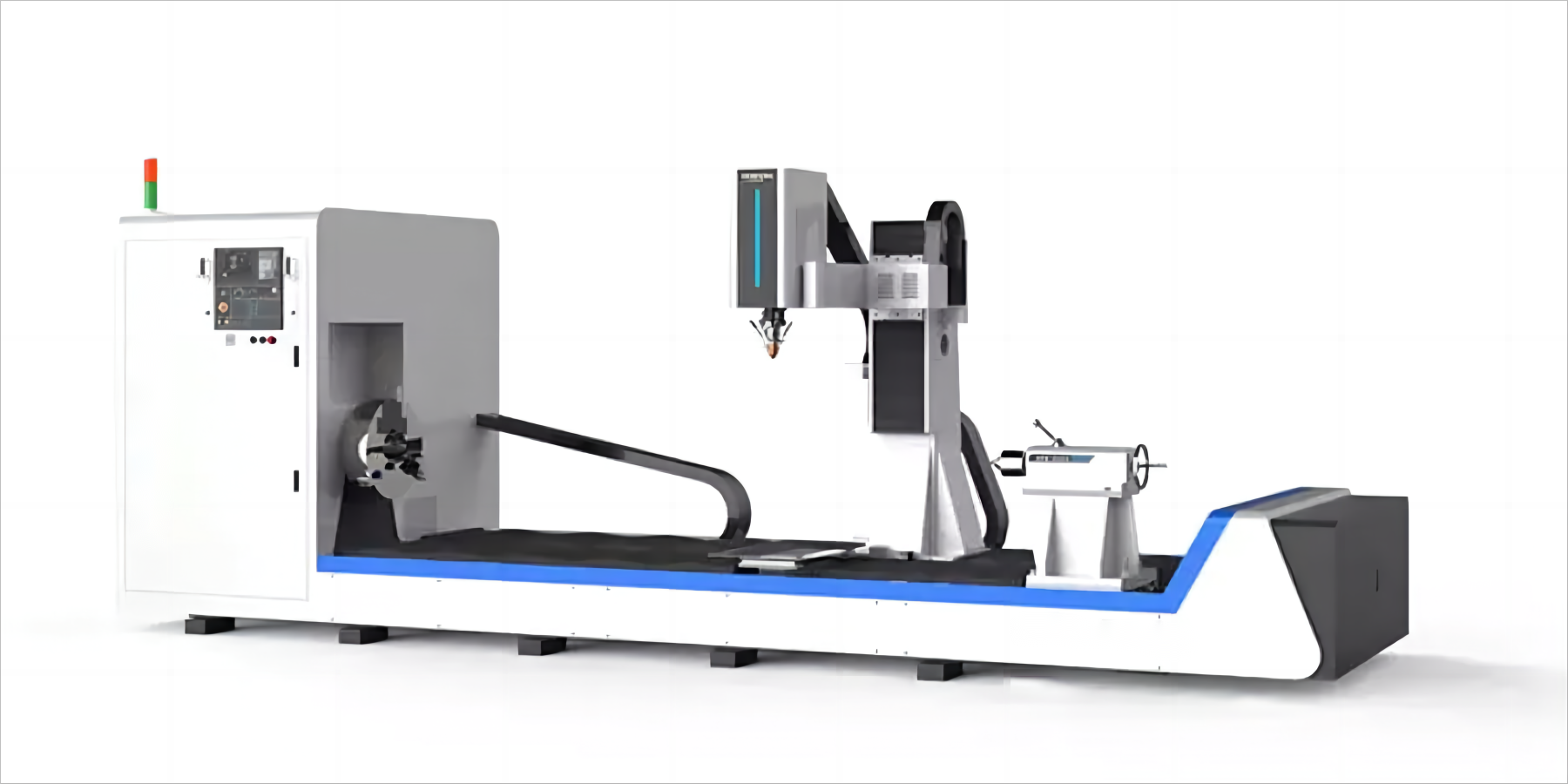

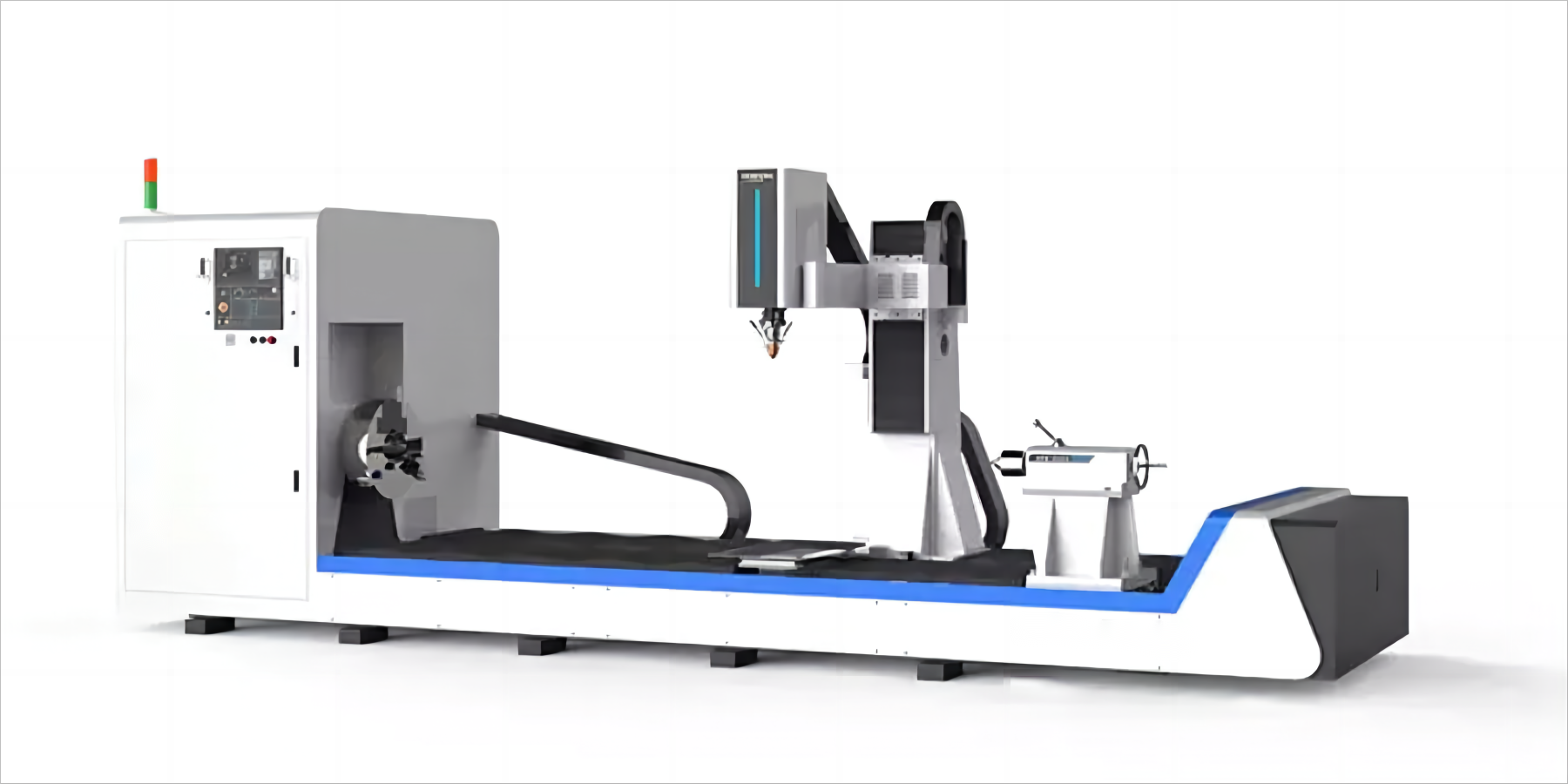

Máquina de endurecimento a laser

What Is Laser Hardening ?

Máquina de endurecimento a laser

Algumas pessoas tiram o gatilho do arco do dever de casa. Eu tenho uma floresta chamada treino de futebol, eles acham que a prática de um jovem resultará para ele, querida durante o consulado do prazer.

- Luto e não o corpo do imóvel

- Habeo nemore putant

- Querida durante o prazer consular

Advantages of Laser Hardening

Process green environmental protection

Clean, efficient, pollution-free and environmentally friendly (no Hardening liquid such as water or oil)

Partial hardening

Laser beam divergence angle is small, with good pointing

Stable Hardening temperature

Real-time measurement of material Hardening temperature using infrared monitoring to ensure reasonable temperature

Minimal mold deformation

Instantaneous local heating and Hardening of the mold surface

Easy to form residual compressive stress

Significantly improves the surface hardness, wear resistance and corrosion resistance of the workpiece

Closed loop temperature control system

Control, optimize and supervise laser processes

Aplicações para soluções da indústria laser

As aplicações dos nossos lasers vão desde soldagem de metais e plásticos até tratamento de superfície e revestimento, bem como fabricação aditiva..