The piston rod is a connecting component that helps the piston perform its function. The majority of it is utilized in oil cylinders and pieces that control cylinder motion. It is a portion of the transmission that is always moving.

Consider hydraulic cylinders as an example. The majority of the surface of the piston rod is damaged by the coating peeling off as a consequence of impact, scratching, or even oil leaking, which impairs the piston rod’s ability to function normally.

Project background

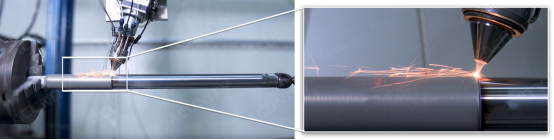

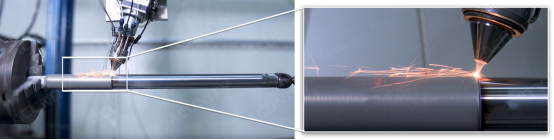

Thin-walled or large aspect ratio items that cannot be processed by conventional laser cladding can be processed without deforming thanks to the low heat input and minimal thermal influence on the workpiece during the cladding process.

Hard wear-resistant coatings made of various materials, including cobalt-based, nickel-based, and composite materials, can be manufactured and applied to the surface of the parts in accordance with various client application requirements. When the coating’s maximum hardness reaches HRC65 or higher, crack control is successfully achieved.