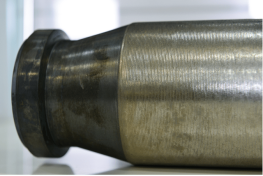

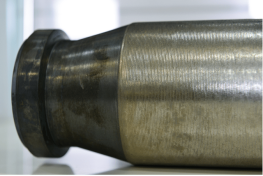

The high-pressure plunger pump is an important equipment in the process of oil and gas exploitation, and is widely used in operations such as fracturing, cementing and water injection. The plunger rod is vulnerable to friction damage caused by high-frequency reciprocating motion, as well as medium corrosion and erosion of hard particles, resulting in a greatly shortened service life.

The traditional repair methods include electroplating, spray welding, etc., all of which have certain defects. Laser cladding has obvious advantages in product quality and influence on the matrix, such as high efficiency, small heat input, small deformation, low dilution rate, controllable thickness of the cladding layer, smooth surface after cladding, and small subsequent processing volume.