Automotive Mold Laser Cladding

Automotive Mold Laser Cladding

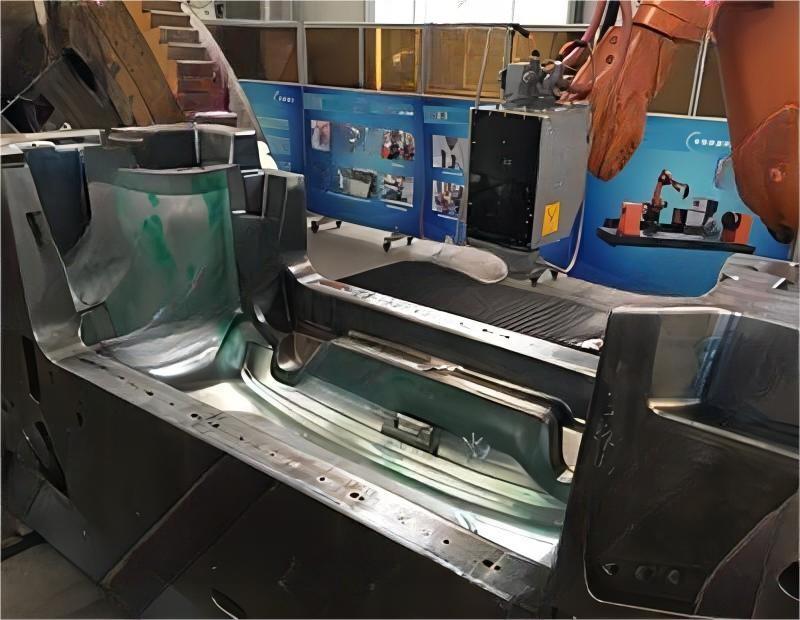

Auto mold is an important basic equipment in the production process of auto parts, but because the production process of auto parts is very harsh, resulting in auto mold

The moulds are deformed, broken and so on. How to improve the service life of the mold has become an urgent problem to be solved.

Project background

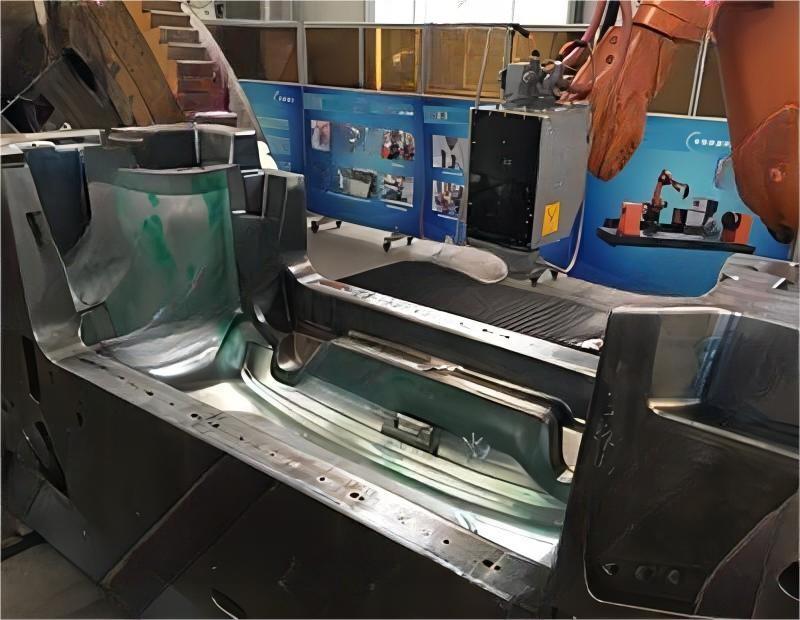

High-energy laser on the surface of the workpiece rapid scanning, the surface of the workpiece in a very thin spot size of a small area

The rapid absorption of energy within a small area of the workpiece surface to instantly make it sharply to high temperature, and instantly complete the low-temperature quenching of high-tech. Not only make the automobile mold to be repaired, and after

After repairing the rail surface hardness, wear resistance, as well as strength and high temperature performance has been significantly improved, while the rail can still maintain a good toughness, so that it

With good wear resistance, high impact toughness, high fatigue strength mechanical properties, etc., the service life of the original parts significantly increased.