High Efficiency Molds Laser Hardening Machine

Home - Laser Hardening Machine - High Efficiency Molds Laser Hardening Machine

High Efficiency Molds Laser Hardening Machine

The High Efficiency Molds Laser Hardening Machine is a powerful, precise and cost-effective tool for hardening of metal molds. With its advanced laser technology, the machine can achieve high hardness levels and uniformity across the entire mold surface. It has a fast and accurate heating process that provides superior heat treatment results in significantly less time than traditional methods.

- On-Site Repair Maintenance

- Compact size

- Convenient transportation

- Easy operation

Technical Parameters of Molds Laser Hardening Machine

Content | Parameters |

Laser | 2-6kW, fiber, semiconductor, disc, etc. |

Robot | Holding weight 16-150kg, wingspan 1600-3700mm, KUKA, ABB, FANUC, YASKAWA, etc. |

Laser Processing Head | 3-25mm round, square spot, size can be customized |

Chiller | Single temperature, dual temperature, cooling capacity according to laser selection |

Optional Accessories | Temperature closed loop, on-line detection, distance detection, offline programming, temperature monitoring, etc. |

Input Voltage | 360-480V Three-Phase Five-Wire System @50-60Hz |

Advantages of Molds Laser Hardening Machine

Lower chance of distortion

In typical hardening processes, the combination of heating the entire workpiece or a larger part of the workpiece and subsequent liquid quenching operations leads in a significant risk of deformation and cracking in the treated workpieces.

Improved compatibility with tiny components

Diode lasers allow for fine control of surface temperature and laser beam placement. This capability enables the process engineer to predictably regulate the heat input, which is crucial for repeatable production hardening procedures.

Reduced processing costs

In comparison to other case hardening procedures like as flame and induction hardening, laser hardening is a non-contact process capable of producing only the appropriate case depth.

Greater part geometries suitability

Flame hardening and induction hardening, for example, have trouble treating workpieces with complicated geometries. Regardless of shape, the noncontact laser hardening technology may selectively case harden workpiece surfaces.

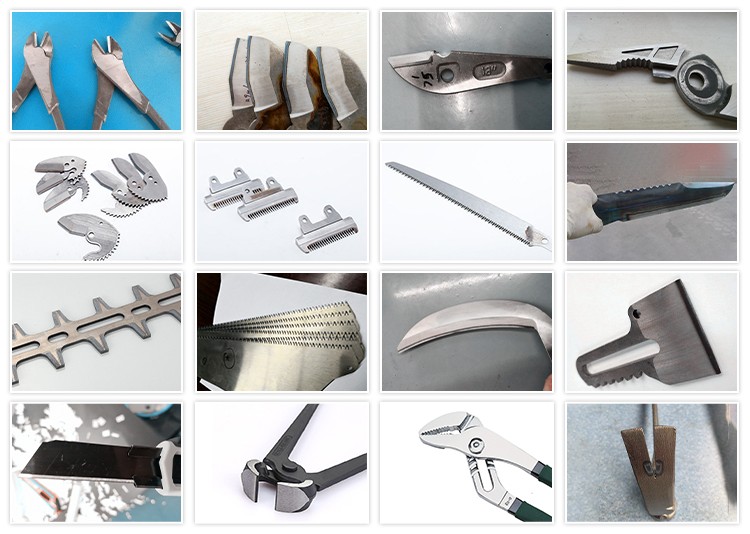

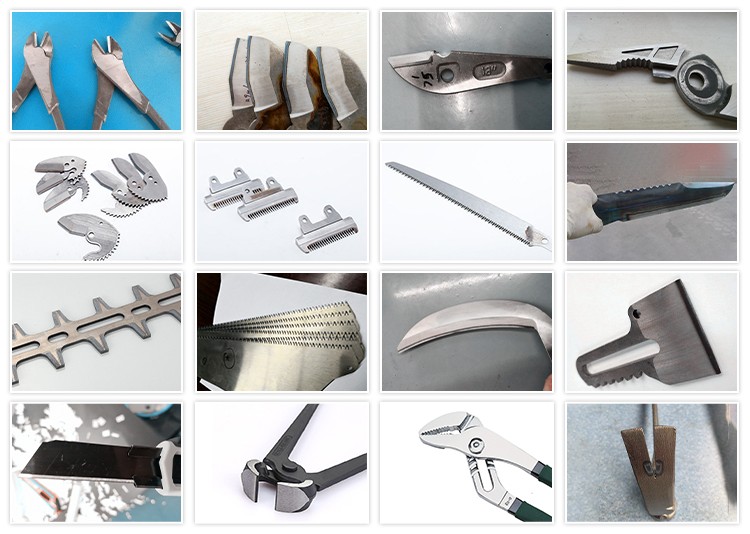

Application of Molds Laser Hardening Machine

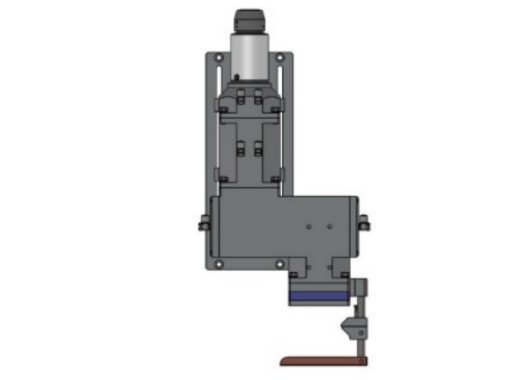

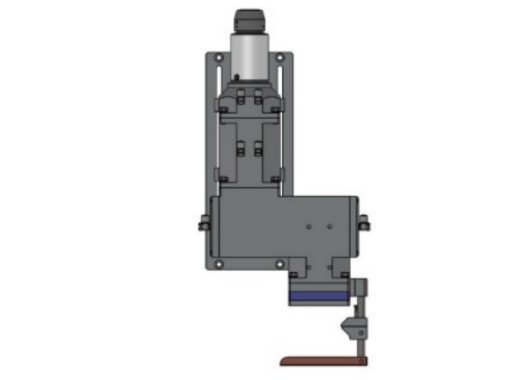

Main Components of Molds Laser Hardening Machine

Laser source

Laser power: 10~ 3000W continuously adjustable, QBH interface, core diameter 600um, length 20m.

Laser head

1. Collimation focal length: 100mm, focusing focal length: 300mm

2. Applicable wavelength: 900-1100nm

3. The powder feeding nozzle contains a water-cooled base

4. Optical fiber interface: QBH

Chiller

Dual temperature control provides cooling water for lasers, machining heads, optical fibers, etc.