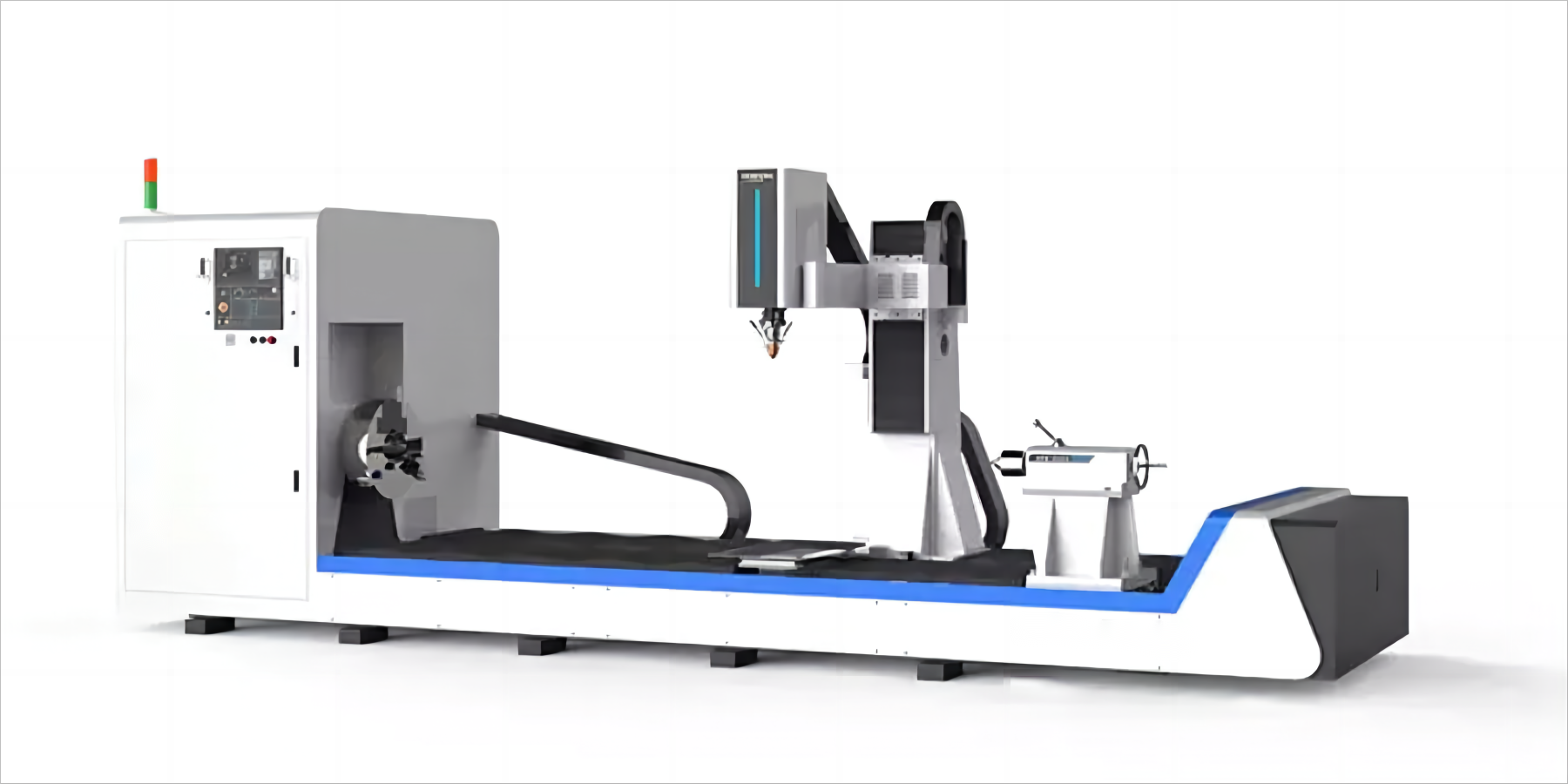

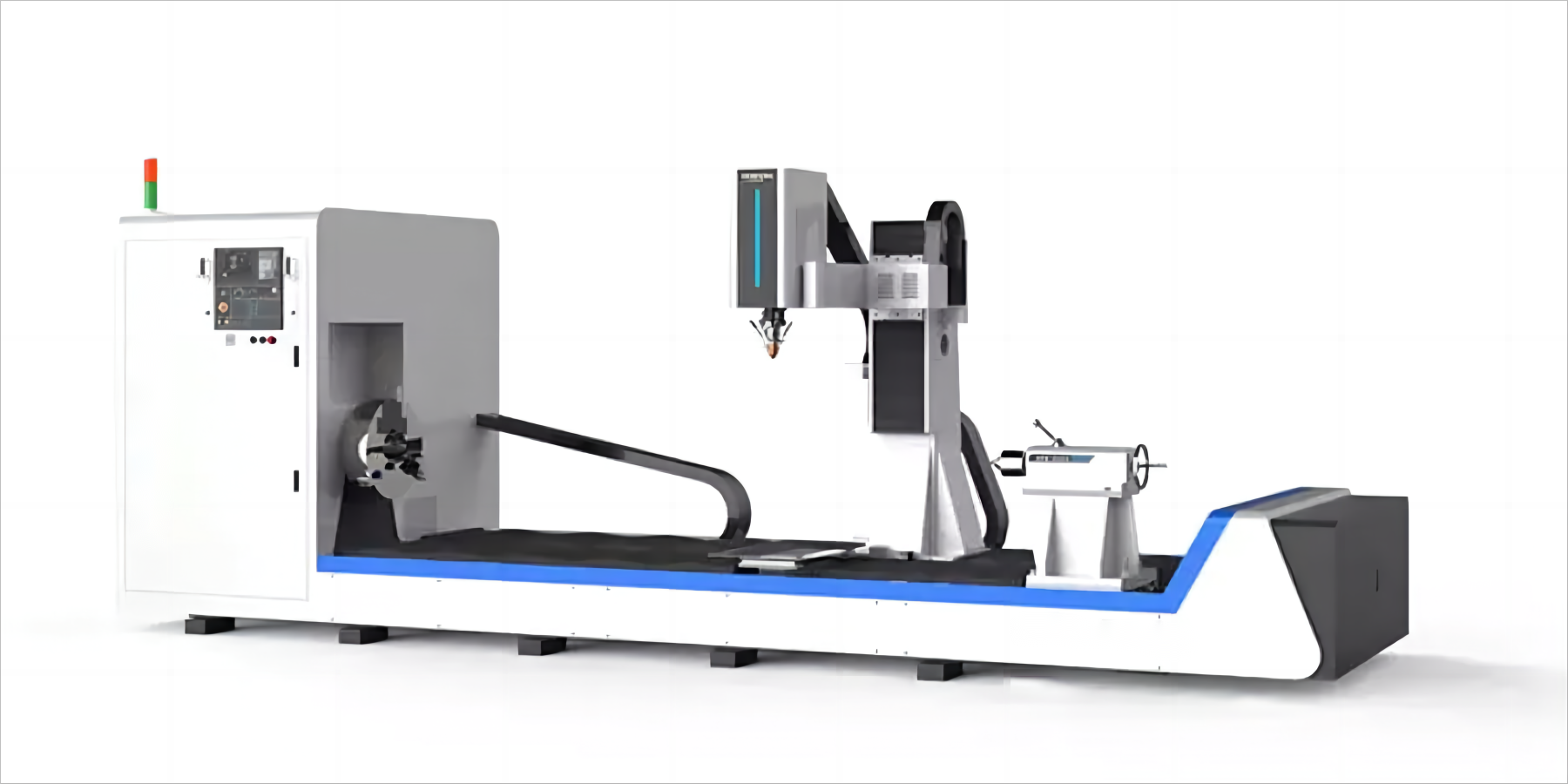

Laser Hardening Machine

What Is Laser Hardening ?

Laser Hardening Machine

Aliquam suscipit felis a arcu laoreet congue. Habeo nemore appellantur eu usu, usu putant adolescens consequuntur ei, mel tempor consulatu voluptaria.

- Luctus nec ullamcorper mattis

- Habeo nemore putant

- Mel tempor consulatu voluptaria

Advantages of Laser Hardening

Process green environmental protection

Clean, efficient, pollution-free and environmentally friendly (no Hardening liquid such as water or oil)

Partial hardening

Laser beam divergence angle is small, with good pointing

Stable Hardening temperature

Real-time measurement of material Hardening temperature using infrared monitoring to ensure reasonable temperature

Minimal mold deformation

Instantaneous local heating and Hardening of the mold surface

Easy to form residual compressive stress

Significantly improves the surface hardness, wear resistance and corrosion resistance of the workpiece

Closed loop temperature control system

Control, optimize and supervise laser processes

Applications For Laser Industry Solutions

The applications of our lasers range from welding of metals and plastics to surface treatment and cladding as well as additive manufacturing.