Glass Mold Repair

Glass Mold Repair

The integral blade disc is a key component of the aero-engine parts, the tip of the blade is easily worn during use, and the blade root ends are prone to cracking failure leading to scrap. The use of laser repair additive manufacturing technology can be achieved in a short period of time to achieve the direct molding of the whole leaf disc, can be a great program to save costs and improve production efficiency.

Project background

Glass mold is the main molding tool for glass products. Cast iron is widely used to make glass molds because of its excellent casting properties, easy processability, and properties such as being hot and non-stick. However, the wear resistance and high temperature oxidation resistance of cast iron materials are not good, and glass molds are frequently exposed to high temperature glass melt at about 1100℃ in the process of use, resulting in sudden cooling and heating of the mold.

At the same time, the jointing surfaces rub and hit each other in the mold opening and closing. High temperature and wear damage make the glass mold in the cavity can still work, the premature destruction of the seam line leads to failure and scrap.

However, with the development of laser cladding technology, its shortcomings such as high temperature preheating, large melt pool depth and heat affected zone, low processing efficiency and low powder utilization rate are gradually exposed. The use of laser cladding technology instead of plasma overlay welding for glass mold seam line repair is highly superior in terms of efficiency, cost and technical effect.

Common glass mold is mainly divided into: primary mold, molding mold, mouth mold from the function. The materials are mainly peristaltic cast iron, gray cast iron, copper alloy, etc.

Project sample

Glass molds often rub and collide with each other during the opening and closing process, resulting in premature destruction of the seam line, thus causing mold wear, corrosion, thermal fatigue cracking and oxidation, and eventually failure and scrap.

In order to enhance the service life of the mold, a new type of nickel-based alloy coating with outstanding high-temperature wear resistance, corrosion resistance, oxidation resistance and high-temperature fatigue performance is currently prepared on the surface of the mold using laser melting technology.

The test and experiment show that the nickel-based alloy coating has excellent anti-wear, corrosion resistance and high temperature oxidation performance, which can greatly improve the service life of the mold.

- Material selection: Nickel-based high-temperature alloy

- Melting equipment: Mobile laser melting equipment

- Laser: Semiconductor laser Four-point nozzle

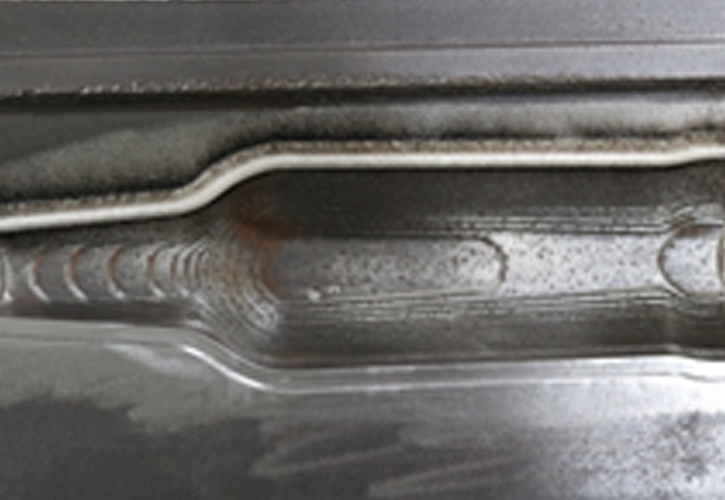

Joint surface before cladding

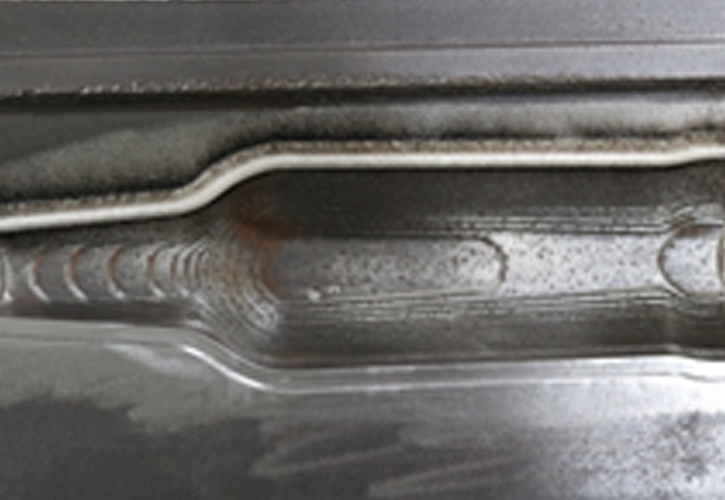

After joint surface cladding

Effect of strengthened glass mold

After cladding, there is no defect in the inspection, and the final result meets the project acceptance standard.