What Is Laser Cladding?

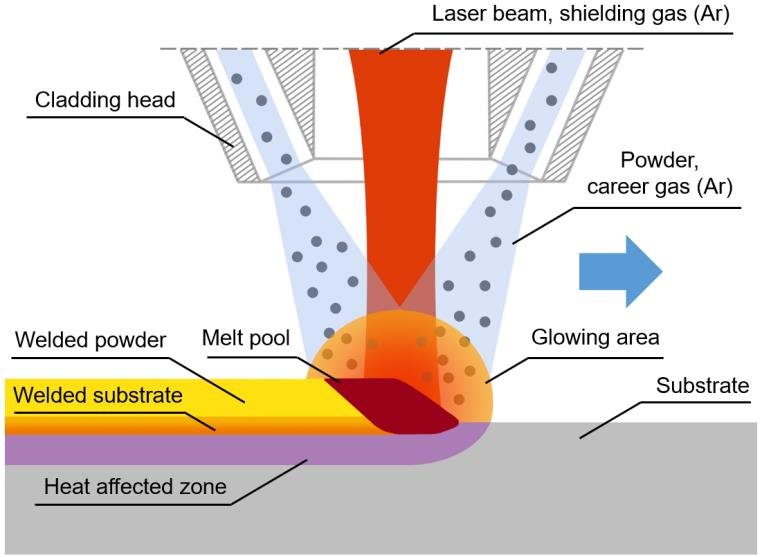

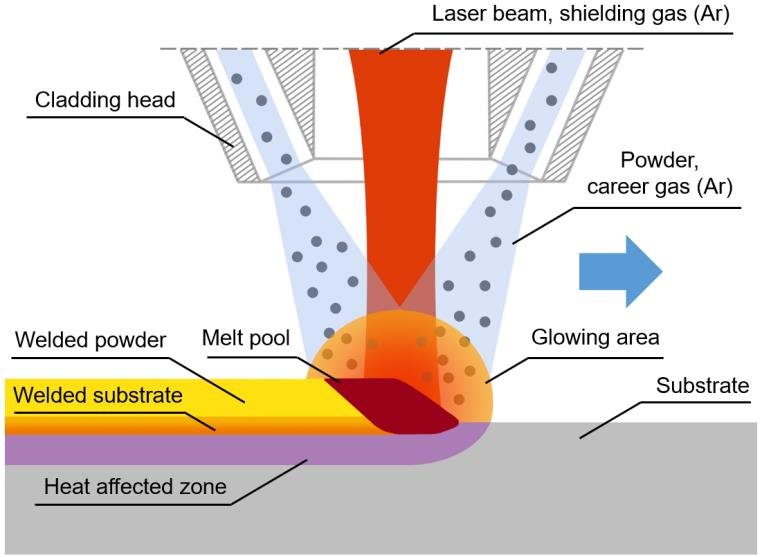

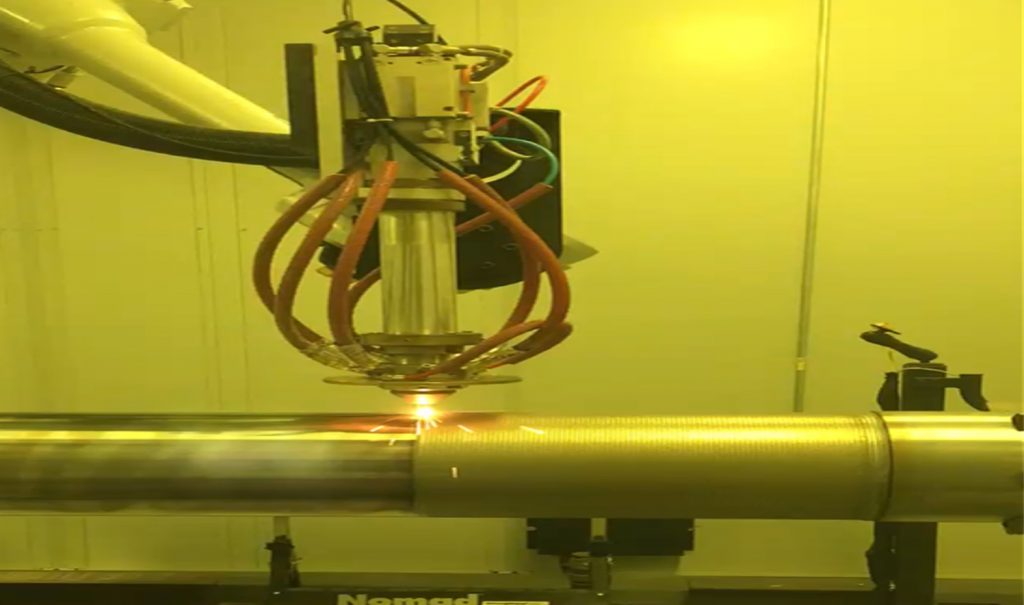

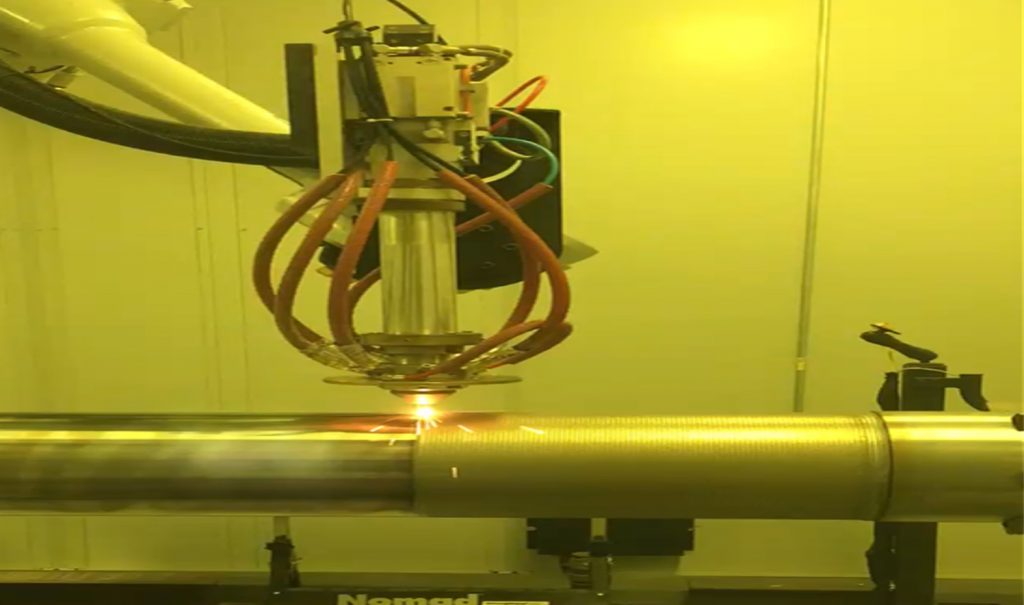

Laser cladding, also known as laser metal deposition, is a technique for adding one material to the surface of another. Laser cladding involves the feeding of a stream of metallic powder into a melt pool that is generated by a laser beam as it scans across the target surface, depositing a coating of the chosen material. Laser cladding technology allows materials to be deposited accurately, selectively and with minimal heat input into the underlying substrate. The laser cladding process allows for property improvements for the surface of a part, including better wear resistance, as well as allowing for the repair of damaged or worn surfaces. Creating this mechanical bond between the base material and the layer is one of the most precise welding processes available.

Read More : Laser Cladding Powder Feeding Method Guide

How Does it Work?

Being able to mix two or more powders and control the feed rate for both separately means that this is a flexible process that can be used to fabricate heterogeneous components or functionally graded materials. In addition, laser cladding allows the material gradient to be designed at the microstructural level due to the localised fusion and mixing in the melt pool, which means that clad materials can be tailored for functional performance in specific applications.

Why is laser cladding an important manufacturing technology today?

By producing protective layers against wear and corrosion, laser cladding improves the performance of industrial items. Engineers may design parts with generic base metal alloys, which helps preserve natural resources. The component is then locally laser clad with a high alloyed material to provide the appropriate performance characteristics.

Laser cladding is also a method that is used to restore and remanufacture high-value components into their original shape. In addition to just fixing the shape of a part, choosing an additive material with superior wear characteristics than the original component improves service life and performance.

| Arc Welding | Thermal Spray | Hard-Chrome Plating | Laser Cladding | |

|---|---|---|---|---|

| Heat Input | High | Low | N/A (chemical process) | Low |

| Dilution Rate | 10 – 40% | N/A(mechanical bonding) | No metallurgical bond | <5% |

| Hardness (HV) | Relatively Low | <1000 | 800 – 1000 | >1000 |

| Distortion | High | Low | N/A | Low |

| Heat Affected Zone | Large and wide | Low | N/A | Low |

| Quality | Less durable | Full of pores and less durable | Prone to chipping and delamination | Highly dense and Long life |

| Pre/Post Treatments | Many | Many | Many | Few |

| Automation | Difficult | Difficult | Difficult | Easy |

| Coat Thickness | >0.020” | 0.020” – 0.040” | 0.002” – 0.006” | >0.020” |

Read More : Laser Cladding VS Thermal Spray

Advantages Of Laser Cladding

When compared to traditional coating methods, laser cladding has various benefits. The benefits of laser cladding include higher quality coating material (including high bond strength and integrity) with less distortion and dilution, as well as improved surface quality. These benefits include:

- low laser exposure duration and depth

- layer and basic material metallurgical relationship

- Thermal spray coatings are less durable than layers.

- good surface quality and little warpage, with virtually no post-processing required

- High energy economy, quick laser cladding process duration

- Can be utilized with a wide range of materials as both the substrate and the layer, including custom alloys or metal matrix composite (MMC) designs.

- Within the deposits, there is little to no porosity (>99.9% density).

- A narrow heat affected zone (EHLA as low as 10m) derives from a relatively low heat input.

- The necessity for corrective machining is reduced when the substrate has little deformation.

Laser Cladding Classifications

There are many variations of laser cladding and laser cladding technology.

The powder is supplied into the path of the focussed laser beam above the substrate during the EHLA process. This ensures that the deposited material is already molten before making contact with the substrate; however, a very shallow melt pool remains on the substrate, allowing the deposited material to cool and solidify in contact with the underlying material, reducing the amount of heat reaching the component below as well as the depth of the dilution and heat effects.

This tiny dilution allows for the production of significantly thinner coatings (20-300m) that attain the necessary chemistry within 5-10m. This is also the foundation of EHLA’s high traversal speeds, which may surpass 100m/min.

Laser Cladding Target Materials

Laser cladding is possible with a range of metals, including:

| Target Material | Typical Hardness (HV) | Thermal Stability (°C) | Application |

|---|---|---|---|

| High Strength Steels (M2, H13) | 550 – 650 | 450 – 500 | Tool repair |

| Rockit™ | 900 – 1100 | – | Excellent substitution for hard chrome, high abrasion resistance at ambient temperature |

| SS309, SS316L | 250 – 300 | – | Used as root layer/build up, relatively good general corrosion resistance |

| SS420, SS431 | 550 – 600 | 500 – 550 | Reasonable wear resistance |

| Stellite-6 | 550 – 600 | 500 – 550 | Excellent galling, wear, erosion, and cavitation protection over a wide temperature range |

| Stellite-21 | 400 – 450 | 500 – 550 | Superior thermal and mechanical shock resistance, relatively high resistance to galling and cavitation |

| Inconel-625 | 250 – 300 | 900 – 1000 | Applied in extremely high corrosive environments, used as buffer layer |

| Inconel-718 | 400 – 450 | 600 – 650 | Age hardenable, high temperature stability and corrosion protection, ideal for hot forging punch |

| NiCrSiB-65%WC | 1500 – 2500 | 600 – 650 | Extremely high abrasion/erosion resistance and excellent for part-to-part sliding wear due to relatively low friction coefficient |

| Colmonoy 69 (NiCrMoCu) | 600 – 650 | 500 – 550 | Excellent resistance to aluminum liquid erosion used in high pressure die cast |

| Ni80Cr20 | 300 – 350 | 1000 – 1100 | Hot oxidation resistance |

| Aluminum-Bronze | 200 – 300 | 350 – 400 | Excellent galling resistance for cold forming tolls, good general corrosion resistance |

Because of the variety of materials available, laser cladding may be utilized for a wide range of industrial applications, including quick manufacturing, component repair, and surface improvement. Tungsten carbide, for example, in an MMC, provides durability, making it perfect for coating applications requiring exceptional wear resistance.

Read More : Laser Cladding Powder Unlimited Guide

Application Of Laser Cladding

Laser cladding is useful for a wide range of industrial applications. These uses range from agriculture and aerospace to drilling, mining, and power generation.

- Flanges

- Seats

- Wear Sleeves

- Pumps

- Glass Molds

- Seal/Bearing Journals

- Impellers

- Rotor Shafts

- Pump Shafts

- Compressor Wheels

- Gearbox Housing

- Propeller Shafts

- Exhaust Valves

- Rolls

- Crank Shafts

- Engine Components

- Mandrels

Drilling tools

High-performance drilling instruments are required for the development of oil and gas reserves. These are subjected to extreme stress and would not have extended lifespans if not protected against wear. That is why, for some time now, special coatings, which are increasingly being achieved with laser coating technology, have become the norm.

Coating of hydraulic cylinders for the mining industry

Laser coating of hydraulic cylinders in technological mining operations such as coal extraction is a rising business. The cylinder’s coating corrodes fast in the local climate, resulting in leaks, thus a replacement or fresh coating will be required.

Until recently, chromium plating was the dominant approach, but laser coatings will gradually replace it because of their greater endurance. The particular improvement in durability cannot yet be defined, although current data reveal a higher than 100% increase in lifespan.

Cutting Tools

Layers of laser clad materials can be utilized to protect saw blades, counter blades, disc harrows, and other cutting instruments from wear and corrosion while also offering enhanced cutting properties. Because of the lack of distortion in this technique, these tools remain straight while variable coating thicknesses may be obtained to meet needs. These coated tools may be used in a variety of industries, including construction and agriculture.

Proven Solution for Hot Mill Rolls used in Steel Making Industry

Rolling steel is a procedure that pushes the performance boundaries of the rolling equipment’s components. Roller and other component failures can be caused by abrasion wear, heat stress, and galling, resulting in downtime and quality concerns. Because of the wide temperature range, a high hardness, low friction solution is required.

Haitian Laser Machinery provides a tried-and-true solution for increasing the service life of hot mill rollers. Customers who have used our laser cladded carbide-based overlays have experienced a 6x increase in service life when compared to thermal spray or arc welding, resulting in decreased operating costs and downtime.

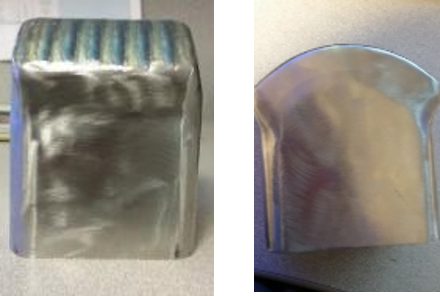

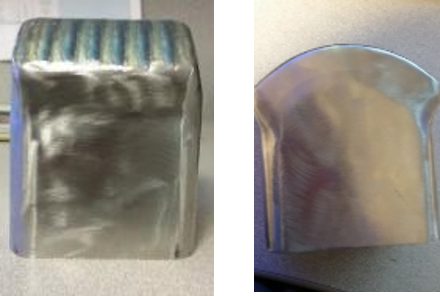

Bottom Punch/Magnet Dies

When producing magnets for motors, the magnet material is blended in a slurry and placed in a die. The slurry is then forced into the magnet die, forcing all of the water/contaminants out. These punches must have non-magnetic tips to avoid interfering with the polarity of the magnet. Furthermore, the dies are vulnerable to significant metal-to-metal wear.

Stellite 6 was traditionally applied to the top surface using GTAW. The dilution line between the base material (W2 steel) and the substrate (Stellite 6) was, however, choppy, and the manual procedure was time intensive (about 1 hour each punch).

To boost efficiency, HaiTian developed an automated approach. A coaxial powder feed laser head was employed in the solution, and bespoke programming was used to map the clad/layer routes.

HaiTian was able to construct a Stellite 6 buildup with a very clear dilution line between the parent and clad material, as well as a cladding in 15-20 minutes rather than 1 hour. As a result, this automated approach significantly increased quality and efficiency.

Wind Turbine Centrifuge Hubs/Shafts

Wind turbine hubs and shafts wear owing to load fluctuation caused by changes in wind speed/intensity. Because of this wear, gearboxes might break early, resulting in expensive replacement costs.

HaiTian used laser cladding on worn hubs, journals, and shafts before machining them to original design specifications. Stainless steels (410 SS, 420 SS, 440 SS) were used as base materials. 420 stainless steel was used as the primary cladding material. Controlling the preheat and process conditions carefully guaranteed that the clad material was defect-free and had similar/improved characteristics to the base material.

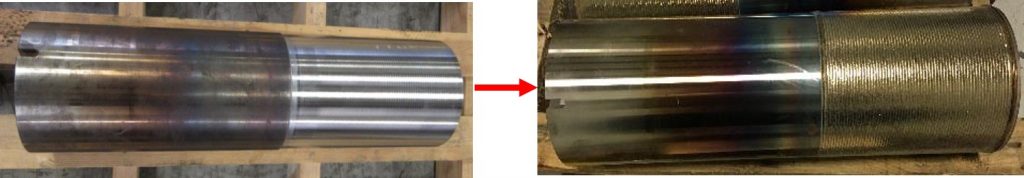

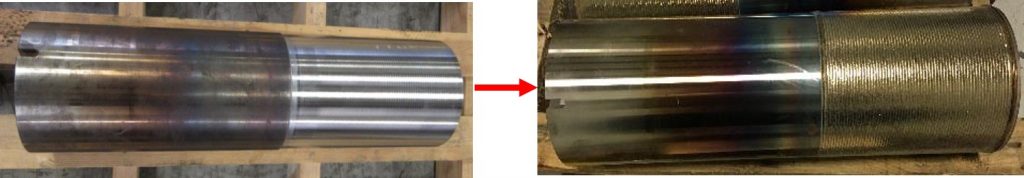

Steel Mill Rods

Steel mill rods are components that are frequently worn. Typically, the wear is minimal yet sufficient to render the rod unusable. IBC Coatings Technologies coat worn rods with lasers. The base material was a high strength steel (4140), and the overlay was 431SS martensitic stainless steel to increase the wear resistance of the substrate.

What Type of Laser Is Used in Laser Cladding?

1. Fiber Lasers

Fiber lasers, which use optical fibers to create laser beams, are well-known for their efficiency and dependability.

2. Diode Lasers

Diode lasers are a type of laser that produces laser radiation via a semiconductor. Diode lasers, which vary in wavelength, power, and fiber type, are used in two types of prostatectomy procedures

3. CO2 Lasers

Carbon dioxide lasers, often known as CO2 lasers, generate laser beams using a gas mixture and are ideal for cladding greater regions.

4. Nd:YAG Lasers

Solid-state crystals are used to create laser beams in neodymium-doped yttrium aluminum garnet lasers. They are adaptable to a variety of cladding applications.

Laser Cladding FAQs

How Does the Laser Cladding Process Work?

Laser cladding works by employing a laser beam to deposit metal from a wire or powder onto a substrate. It melts at the same pace as it is fed onto the substrate by the laser. A metallurgical connection is formed between the molten liquid and the substrate when it solidifies. This technique allows for perfect control of coating thickness, content, and surface properties.

What Is the Purpose of Laser Cladding?

Laser cladding is used to repair damaged or worn surfaces while also providing a protective layer for the object. It allows customers to fine-tune the process, resulting in enhanced surface qualities and durability.

Why Is Laser Cladding Important?

Laser cladding is important because it can accurately repair, enhance, and protect surfaces. It outperforms conventional methods by leaving fewer heat-affected zones, producing less waste, and being compatible with a wide range of materials. Overall, it’s a versatile and efficient procedure.

What Are the Key Parameters that Affect the Quality of a Laser Cladding?

Substrate type, process environment, scanning speed, powder feed rate, powder composition, and laser power are all critical parameters that determine laser cladding quality. These characteristics have a direct influence on the cladding shape, bonding, porosity, and surface polish. To get the required clad quality and qualities, they must be appropriately managed and modified.

How Does Laser Power Affect the Laser Cladding?

Higher laser power enhances cladding material melting and bonding, resulting in greater adhesion. It allows for thicker layers and greater penetration. However, it must be appropriately adjusted; too much power can cause thermal damage, while too little results in poor bonding. The right power level is critical for the optimum cladding quality.

Can Metals Be Used in Laser Cladding?

Yes, laser cladding is possible with metals. Metal alloys such as stainless steel, nickel-based alloys, titanium alloys, cobalt-chromium alloys, and aluminum alloys are preferred candidates due to their better mechanical qualities and ability to create metallurgical connections during the cladding process.

How Much Does a Laser Cladding Machine Cost?

The cost of a laser cladding machine is largely influenced by its size, features, and productivity. A large-scale machine may cost between $250,000 and $350,000, whereas a small-scale one could be approximately $100,000. There are, however, less costly variants ranging in price from $900 to $11,000.

How Long Does Laser Cladding Machine Last?

The longevity of a laser cladding machine is determined by how it is used and maintained. Under normal conditions, most laser machines can live up to 15 years. This will vary based on numerous factors, including the laser’s design and construction, the operating power utilized vs the rated power of the device, and the laser’s operating temperature.

What is the difference between laser cladding and laser welding?

Cladding and welding — There are significant differences between laser welding and laser cladding. Both link two materials, but laser cladding generates a new surface by covering a substrate with another metal. Meanwhile, laser welding joins two workpieces.

Is laser cladding better than metal spray?

The easiest approach to pick is to determine exactly what you want in a surface repair or coating. If a metallurgical bond is required but temperature is a concern, laser cladding is the way to go. Thermal spray is a good option if you require a thin layer of material.

Summary

This article introduced laser cladding, described it, and explored the various procedures and varieties. Contact Us representative to learn more about laser cladding.

More Article

- Laser Cladding VS Thermal Spray:What is the difference?

- Laser Cladding Process

- Laser Cladding Vs Laser Hardening

- Laser cladding vs Electroplating

- Laser Cladding VS Chrome Plating

- Laser Cladding Vs Additive Maufacturing

- PTA Welding Vs Laser Cladding

- 3d Laser Cladding Vs Laser Melting

- Laser Cladding vs Laser Alloying

- What Is The Difference Between High-Speed And Regular Laser Cladding?

- Laser Cladding Powder Feeding Method Guide