With the growth of science and technology in recent years, high-speed laser cladding has grown significantly, and laser industry and metal surface processing sector have also attracted significant and broad attention. The major reasons are: high-speed laser cladding provides higher processing efficiency, higher processing precision, lower future processing costs, and a minimal quantity of heat input to the workpiece, which can decrease workpiece deformation, among other benefits.

What is High Speed Laser Cladding

EHLA, also known as extreme high-speed laser cladding, is capable of speeds 10 times faster than traditional laser metal deposition (LMD) in terms of surface coverage rate.

The technique has demonstrated the ability to achieve cladding speeds in excess of 300m/min and surface coverage rates of up to 2.0 m2 per hour.

For corrosion and wear protection, EHLA can be utilized as a cost-effective alternative to hard chrome plating and thermal spray methods. The coating is metallurgically attached to the base layers via the fusion process, which means it will not chip, peel, or delaminate and, since it is non-porous, provides more efficient protection than competing approaches.

How Does EHLA Differ From Laser Cladding?

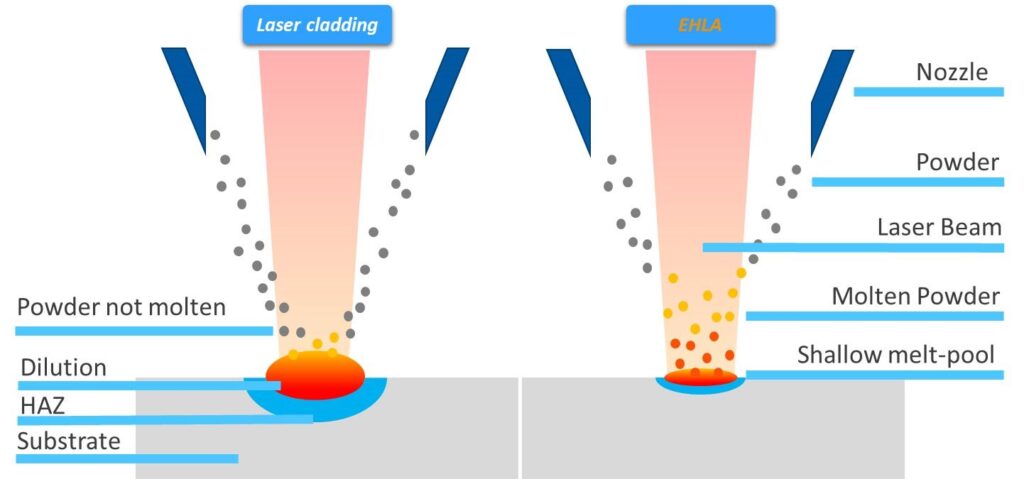

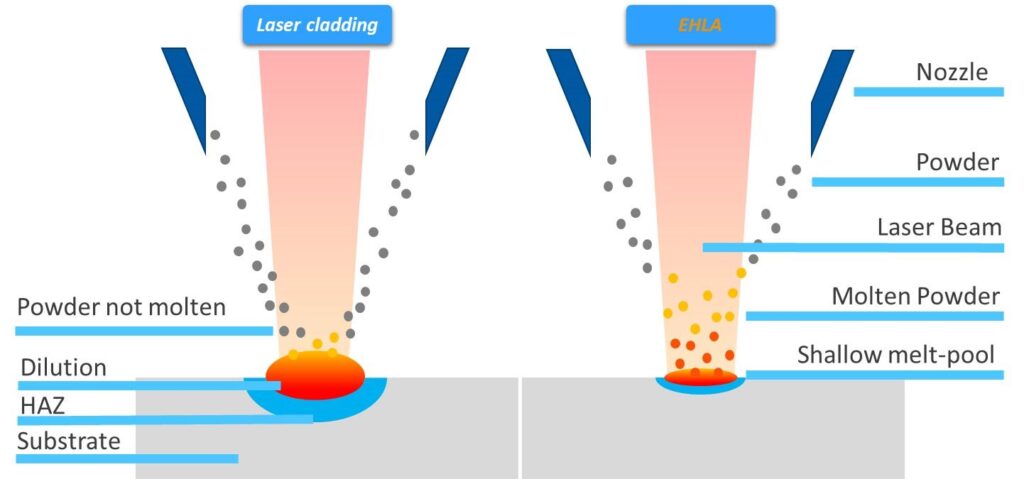

An optically focused laser beam forms a melt pool on the surface of the component by laser radiation, powder or wire is fed into the melt pool via a nozzle, and melts using a combination of melt pool temperature and laser radiation to add form and function. The heat source travels away as the nozzle crosses the substrate, and the deposited material hardens and consolidates onto the substrate, leaving a zone of dilution material (300m-1000m deep) between the substrate and deposit.

The powder is supplied into the path of the focussed laser beam above the substrate during the EHLA process. This ensures that the deposited material is already molten before making contact with the substrate; however, a very shallow melt pool remains on the substrate, allowing the deposited material to cool and solidify in contact with the underlying material, reducing the amount of heat reaching the component below as well as the depth of the dilution and heat effects. This small dilution forms the capability for producing much thinner coatings (20-300µm) that achieve desired chemistry within 5-10µm. This also forms the core of the high traverse speeds achievable with EHLA.

The advantages, limitations, and similarities between high-speed laser cladding and traditional laser cladding are outlined below:

Common Points

We will Show Common Points Between High-Speed Laser Cladding And Conventional Laser Cladding

(1) The process concept is the same: laser energy melts the metal powder and the surface of the substrate to generate a coating layer on the substrate’s surface.

(2) Cladding materials are plentiful: materials that can be clad by conventional laser cladding can be fused by high-speed laser cladding; and some materials that cannot be clad by conventional laser cladding, such as high melting point materials, can be welded by high-speed laser Head cladding melts.

(3) Common process pathways: The adjustment locations for the traditional laser cladding process are also the adjustment points for the high-speed laser cladding process.

(4) The cladding layers are all metallurgical combinations: on the typical cladding surface, the cladding layer has evident grooves and substantial variations, but the coating effect of high-speed cladding is similar to thermal spraying and the surface is smooth.

(5) The application sectors are essentially the same: high-speed laser cladding may be used in places where conventional laser cladding cannot be used, and it can also be used in locations where conventional laser cladding cannot be used. In layman’s words, high-speed laser cladding can accomplish things that ordinary laser cladding can’t, and it can do things that typical laser cladding can’t.

Advantages Of High-Speed Laser Cladding

(1) High efficiency and quick speed: Processing efficiency (0.5-1.5m2/h), line speed up to 100m/min, significantly improved cladding efficiency. The 70-inch-diameter alloy steel substrate is coated in martensitic stainless steel. The coating is 0.5mm thick. The cladding efficiency may reach 1.2m2/h when the overlap is 70%, and the overall processing efficiency is 3-4 times that of traditional cladding.

(2) Smooth and smooth cladding layer: After the cladding is finished, it may be immediately honed and polished without turning, resulting in significant material and processing cost savings.

(3) The cladding layer might be thin as well as thick: Thin cladding (0.2mm-0.3mm), medium cladding (0.3mm-1.5mm), and thick cladding (0.3mm-1.5mm) are all possible. , thickness, and in some cases, multi-layer cladding may be achieved, which is convenient and quick.

(4) The heat input is low, and the workpiece does not distort easily: High-speed cladding has a low heat input to the workpiece, a low degree of thermal distortion of the workpiece, and it may be utilized to process thin-walled and tiny components.

(5) Slow dilution: The dilution rate may be adjusted to 3%, which helps to preserve the cladding coating’s high-quality performance.

(6) Nonferrous metals that can be processed: It is highly ideal for non-ferrous metal research and analysis because it can accomplish surface strengthening of non-ferrous metal materials such as copper, aluminum, titanium, and so on.

(7) The power density of the laser welding joint is high: It is capable of cladding high melting point powder materials.

(8) Energy conservation and environmental protection, with widespread application:During the high-speed cladding process, no three wastes are formed, breaking the restrictions of several traditional cladding application domains. It is widely marketed and used in a variety of applications. It is presently a viable and successful method of replacing electroplating.

Disadvantages Of High-Speed Laser Cladding

(1) The powder usage rate of high-speed cladding is now at 70%, which is slightly lower than that of conventional laser cladding. It needs to be enhanced further via technological ways.

(2) High-speed laser cladding often employs fine spherical particles of 20-53um to achieve greater surface quality, therefore conserving resources and lowering processing costs, whereas conventional laser cladding generally uses coarse powders of 50-150um. Fine powder is somewhat more expensive than coarse powder.

(3) High-speed laser cladding is a novel technique with a little more sophisticated procedure than traditional cladding.

What are the Applications of EHLA?

EHLA is primarily geared at coating components, making it a viable technology for any area with components that are subjected to severe wear or are at danger of corrosion, or a combination of the two. Examples of such applications might include:

- Disk brakes

- Cylinders hydraulics

- Journal Bearings

- stems and valves